Polyester cleanroom wiper and types of the edges

Polyester cleanroom wiper

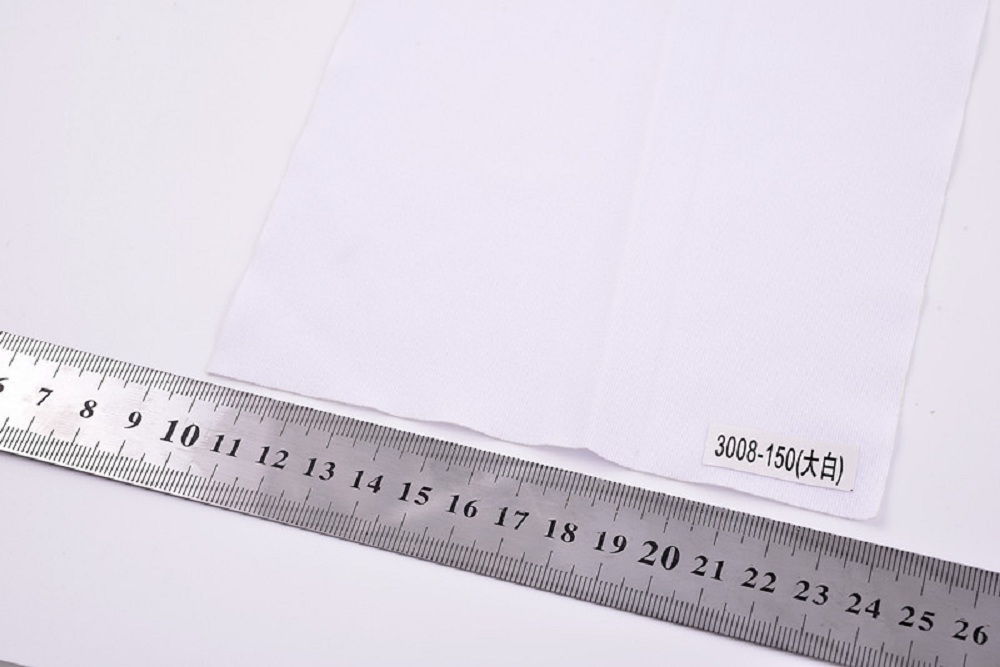

Comprised of 100% ultra pure continuous filament polyester yarns that are especially absorbent and clean. These wipes are laundered and packed in a Class 100-1000 cleanroom laundry. Abrasion resistance Polyester Wipers are laser cut to reduce particles and feature sealed edges for applications where scratching is a concern. Designed for extra absorbency and wiping efficiency.

Xiongbao wipes are a low linting, fast-drying wiper available in many sizes. They are used for cleaning and wiping applications in microelectronics, semiconductor and aerospace.

Knife cut edges provide a very soft edge which is also non-abrasive. The cutting process, generally conducted with a steel blade, generates the most extraneous fibers or loose ends for cleanroom wipe cuts. This is the most economical option for less critical cleanroom application but also the most prone to linting or particle shed.

Laser sealed edges provide extremely precise edges with minimal disruption of surrounding material. The process ensures zero loose particles or split end for ultra-clean, heavy duty cleaning. The laser process does entail trace amounts of carbon deposit.

Ultrasonically sealed wipes impart an ultrasonic heat process which melds fibers without the need for cutting by knife or the carbon deposit of laser cuts. The result is a cleanroom wipe with lower carbon levels, and a precisely formed, stable edge. Ultrasonically sealed wipes provide the highest grade of particle retention and the most cleanliness.This is the most economical option for less critical cleanroom application but also the most prone to linting or particle shed.

评论

发表评论